618

Process automation is one of the most effective ways for dairy processors to meet current demands for quality, food safety, and economic efficiency. New technologies allow full control over pasteurization, fermentation, packaging, and storage processes, with a high degree of precision and predictability.

SCADA systems and PLCs (Programmable Logic Controllers) are widely used in modern dairy processing facilities to monitor critical parameters in real time—such as temperatures, pressures, and processing durations—and to trigger automatic interventions in case of deviations. These systems reduce human intervention, minimize errors, and ensure consistent recipe replication.

"Smart factory" technologies, including IoT sensors and predictive analytics solutions, enable predictive maintenance of equipment, preventing unplanned downtime and reducing idle time. At the same time, automation ensures complete digital traceability, from raw material to the final packaged product.

In Romania, more and more large factories are implementing such solutions through European co-financing, as the initial investment is recovered through reduced technological losses and lower operating costs. Another advantage is scalability—automated lines can be easily adjusted to changes in production volume or product range.

Automation also enables the launch of innovative products—such as multi-layered yogurts or fermented dairy beverages with precise microflora profiles—that are difficult to produce without strict digital control. In a highly regulated sector, processors who adopt these technologies strengthen their market position and become more resilient to shifts in the European market.

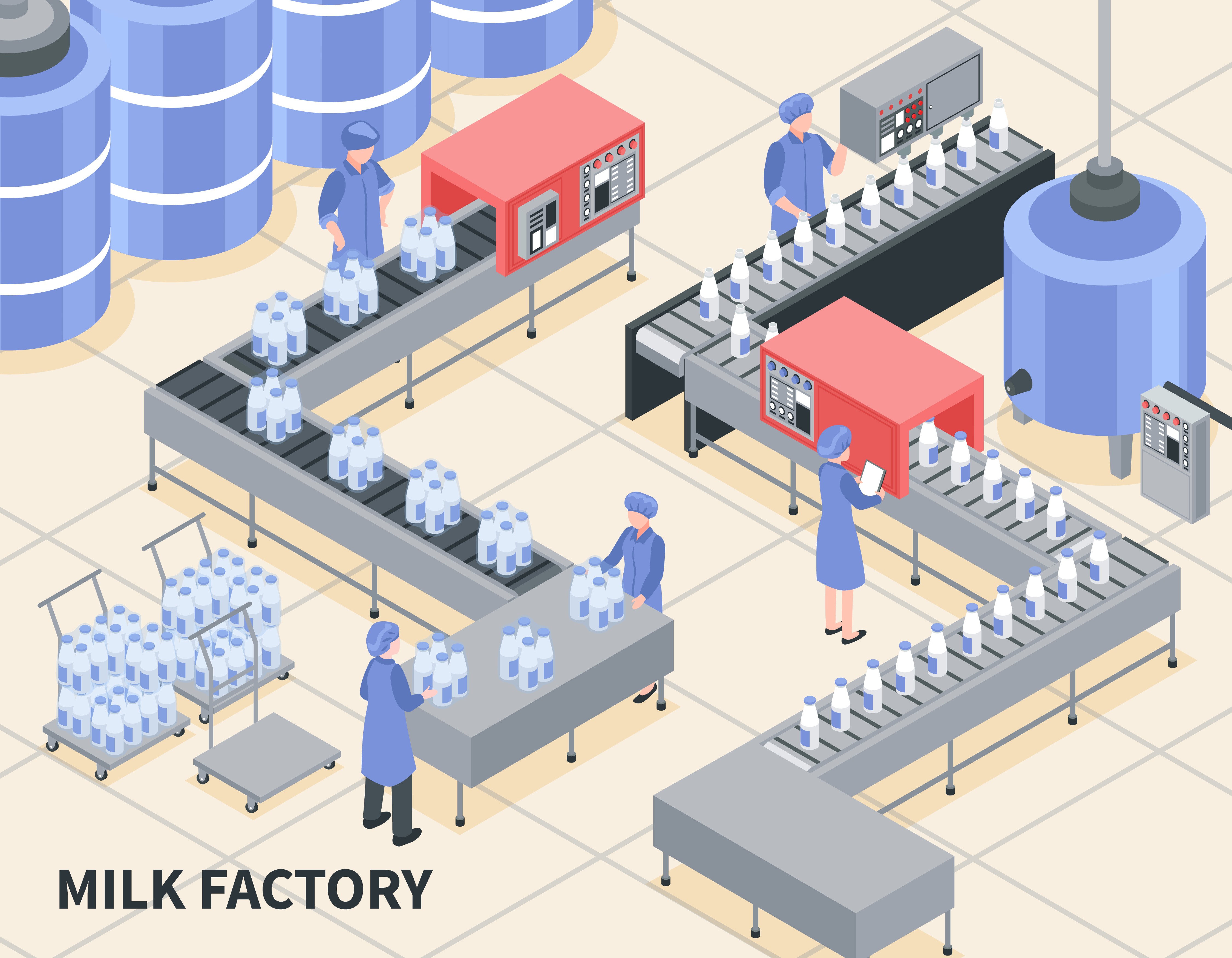

(Photo: Freepik)